The Definition of Earthing

Main earth mass may be used as a constant and unchangeable reference of potential (0). This zero point may be used for all systems which need earth. Practically, all conductive components and bodies of electric equipment may be directly connected to this potential reference (earth).

When there is an unwanted short connection to electric equipment body, metal pieces without connection to earth are in phase potential and humans in touch with them may harvest dangerous potential difference and be hurt.

The Basis of Earthing

Earthing is done for two reasons, correct function and behavior of electric systems, in other words protecting equipment (electric grounding) and another one protecting people who are in touch with equipment (protective grounding).

The Applications of Earthing System

-

Protecting humans and equipment (protection & safety)

-

Correct performance of electric power system (functional & operational)

-

Transferring instantaneous currents resulted from electrostatic discharge and atmospheric events (EMP, ESD)

-

Suitable protection and performance of telecommunicational and data equipment (EMC)

If you need further guidance, you can contact our experienced specialists for information and product purchase.

The Application of Earthing System in 1KV Power Installations (According to EN50179 and VDE0141) Standards

- Installations and metal components of HV and MV systems have not been a part of electrical network but carry electric current in connections (for example, metal components and generator bodies, transformers, capacitors and electrical enclosure) have to connect to site earthing system.

- Metal pieces and conductors which may become an electric current path (like cable trays and ladders, metal pipes and ducts, building structures and…) have to be also connected to earthing system.

Some of Applications of Earthing System

-

Building earthing system

-

Telecommunications power earthing system

-

Apartment earthing system

-

Light tower earthing system

-

Solar power station earthing system

-

Guyed tower earthing system

-

Closed-circuit television camera earthing system

-

Shed earthing system

-

Fuel tank earthing system

-

Petroleum reservoir earthing system

-

Tower crane earthing system

-

Metro station earthing system

-

Aviation equipment earthing system

-

Meteorology equipment earthing system

-

Sport stadiums and golf course earthing system

-

Open warehouse earthing system

Types of Earthing Grid Electrodes

Earthing grid electrodes are divided into two types of natural electrodes and artificial electrodes.

Types of Natural Electrodes

-

Cables conductive sheath

-

Structures metal components

-

Structure armatures

-

Installations plumbing

-

Any underground metal installations in touch with earth and there is no obstacle using it as earth and atmosphere electrode.

Types of Artificial Electrodes

-

Dip conductors (rods, pipes, sheets and…)

-

Horizontal conductors (copper wire, mesh, foundation armature and…)

Types of Earthing Electrode Array

Earthing grid electrodes may be implemented deeply or superficially or a combination of both based on equipotentiation principle.

Array Type A

Ground station system type A is used for small and low important buildings (residential) or existing structures without any other type of construction and or Lightning Protection System (LPS) using stretched rods or wires.

Array Type B

Ground station type B is suitable for buildings with gridded conductors in their protection system and so many lightning conductors.

The Characteristics of Earthing Grid Electrode

-

Earthing electrode grid has to be installed at suitable points of sites so that step voltage difference be minimized.

-

Electrode burial depth and its type has to be protected from freezing, dryness and corrosion and has relatively monotonous and stable resistance throughout its life.

-

Dip electrodes are also suitable to disperse DC currents and or urban electricity frequency, when the increase of depth increases soil electrical conductivity.

-

If armatures inside foundations are used as earthing electrode, the connections have to be perfectly suitable electrically and mechanically.

If you need further guidance, you can contact our experienced specialists for information and product purchase.

Earthing Grid based on Earthing Foundation-(IEC62305 Standard)

Earth foundation is the best solution to implement wide and suitable earthing grid to protect structures (form EMC perceptive), considering the presence of humans and sensitive equipment. Therefore, it is necessary to consider essential preparations from the beginning of construction operation and before implementing structures foundation.

Wide and interconnected armature grid of building foundation has made it possible to provide at least suitable bonding grid using extra auxiliary armatures and connecting them to existing armatures to remove inductive field and shock currents and transferring them with the lowest impedance to earth mass on buildings floor.

Therefore, the highest volume of continuity among armatures has to be provided correctly arranging auxiliary rods and conductors above foundation armatures inferior grid and connecting to a part of armatures by clamp or welding. Dimensions of auxiliary mesh and its boding distances with structure metal pieces and type and cross-sections of conductors have to be considered based on standard minimums.

Earth terminals are predicted in suitable areas to distribute earth in equipotential interior and exterior spaces.

Supplying Companies and Different Earthing Brands

The items of earthing system are mostly produced and manufactured inside our country.

Earthing Equipment and Tools

The tools necessary to implement earthing system are as follows.

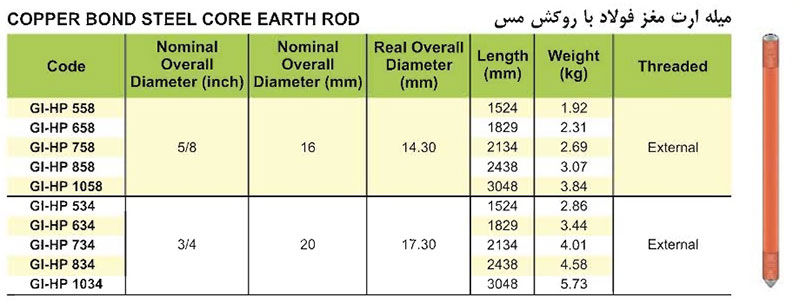

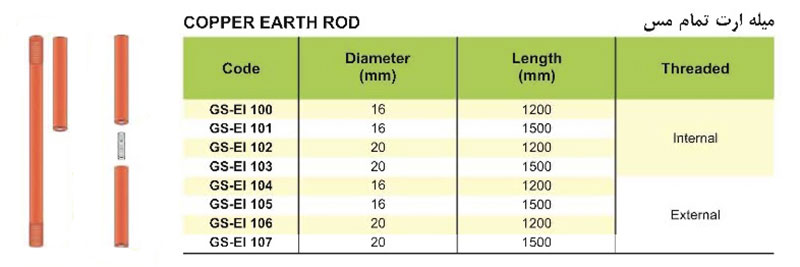

Different Types of Earth Rod Existing in Espak Co

- Copper coated steel core earth rod

- Full copper earth rod

- Stainless steel earth rod

Earth Rod

Security earth rods are manufactured by Espak Co in Axis Factory in India. The thickness of copper created on rod steel core by electrolysis is 256 µ. The core of rod has been selected from SAE 1010/1020 steel to have enough mechanical resistance against stork and ductility. Axis earth rods have UL467 standard confirmation and have better mechanical resistance, higher lifespan ad standard defined conductivity compared with earth rods existing in market.

Types of Clamp

Double groove, double screw clamp

A kind of brass clamp to connect earth wires up to 120 mm2 cross-section to each other.

Welding cylinder

A piece for welding to metal structures to connect earth wires to metal structure.

Roll bolt

It is a kind of bolt and nut fitting has been first introduced by Hilti Co. Roll bolts have been made up of one conical head screw, one slotted metal cylinder, one nut and one washer. Roll bolts are based on increasing the volume of connection that is something like bolt and rawlplug fitting on the surface of walls. Roll bolts are used to connect metal sheets on concrete, rock and… surfaces in structures and building.

Thread seal tape

A kind of pitch tape to thread seal earthing system fittings.

X-joint

A kind of brass clamp to connect wire up to 70 mm2 cross-section to belt up to 30x30 mm as two, three and four way.

Conductor to armature connection clamp

a kind of brass clamp to connect earth wire to armature in different sizes.

Belt to wire connection clamp

A kind of special clamp to connect wire to belt for branching (useful for implementing data centers earthing system).

Armatures to each other and wire and belt to armature connection clamp

steel copper clamp for armatures.

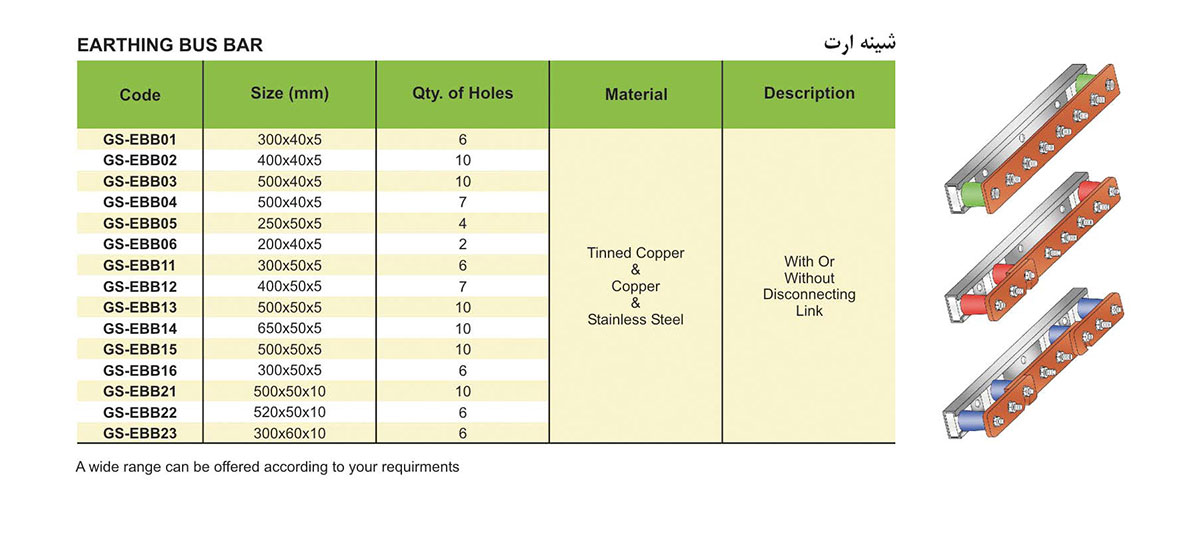

Earth busbar

all generators, transformers, wires and cables of a power plant with equal voltage are connected to each other using an ingot or a conductor called busbar in each phase. All energy of generators and transformers or both of them join each other in busbar and are directly guided to other consumers or busbars using step-up or step-down transformers with another voltage. Therefore, busbar is considered as a tool to collect and disperse energy in that unit.

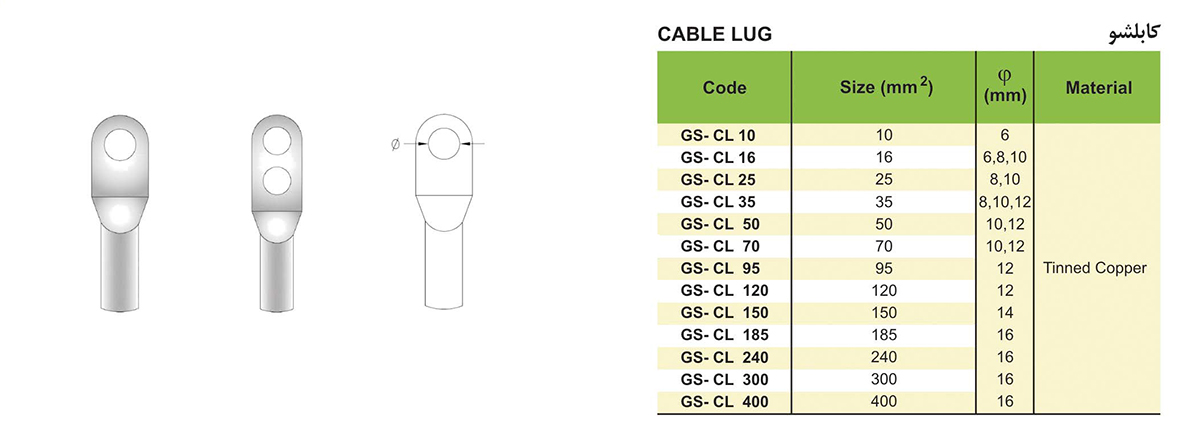

Cable shoe

cable shoe is used to connect cable conductor to busbar and other connection areas. Cable shoe is made up of copper conductors and tinned copper and aluminum is used for aluminum cables. Also, Bimetal cable shoe used to connect aluminum cables to copper busbar.

Earth Plate

A brass (stainless steel) piece that can be used in the implementation of the foundation earthing system to connect to the reinforcements and create a point outside the concrete for branching the earth.

C-CLAMP

C-clamp made of copper alloy used to connect two cables in parallel or to branch from a grounded copper cable or wire.

If you need further guidance, you can contact our experienced specialists for information and product purchase.

Aluminothermic or explosive welding operations

Items related to Explosion Welding

-

graphite mold

-

welding powder

-

cleaning kit including wire brush, gloves and eyeglasses

-

cleaning spinner

-

lighter

-

holding handle

Explosive Welding Catalog

Graphite mold

is one of the main pillars of aluminothermic welding. Good mold is the one which gives the predesigned figure of welding well. It doesn’t allow melted material escape, it expands easily after welding and well tolerates at least 50 welding. The code of each mold has been carved on a metal plaque has been installed on the body of mold.

Welding powder

is usually a mixture of copper oxide and aluminum which is packaged in cardboard capsules based on type and weight, each capsule contains some specific amount of welding powder and enough amount of explosive detonator at the bottom of capsule. Capsules are packaged with closer sequins in a lidded can and are arranged in a craton. These materials are transported without special care and are not capable to be suddenly exploded in the absence of spark.

Mold handle

usually every mold is made up of two or three graphite pieces and the handles are designed in such a way that compress graphite pieces with toggle mechanism so that melted materials cannot escape when welding, some standard handles are made for widely used models but sometimes special handles are needed for special handles.

Lighter

in order to start the process of welding suitable lighter must be used, a lighter which throws spark.

Cleaning spatula

Special spatulas whose profile is designed according to the profile of the mold blast tank and are used to clean the mold after each weld.

You might also be interested in the article "RED Device"!

Parameters Determining Price and Cost of Earthing System

Usually, arrangement, material of earth electrode and soil resistance are the most important parameters in determining the price of earthing system.

The Services and Pieces Supply

Espak Co doesn’t have any agencies to sell earthing items and it sells and installs earthing systems in towns itself.

Design principles and lightning arrester installation:

Designing and installing earthing has to be based on IEC62305 standard.

Earthing course

During its presence at earthing system, Espak Co has held various educational seminars.

These seminars include passive and active lightning arresters, earthing systems and protecting electronic equipment against voltage surge (surge protection).

This company is able to hold educational seminars and classes requested from clients.